Replacement Filters For SoFrance | Find Your Filter Solution

Our team of replacement filter specialists at Fluitek can help you find the SoFrance filter replacement you need. As a national company with over 35 years of experience, we have the knowledge and passion to help you choose one of our replacements that exceeds the OEM's quality but for a lower price.

SoFrance is just one of the thousands of brands we have filter solutions for. Read on to learn how we can help you find the right filter.

What Is SoFrance?

Sofrance is a subsidiary of Safran Group, a Paris-based company that develops solutions for filtering fluids and gases to protect equipment in the aeronautics, defense, and space industries. SoFrance provides solutions across many sectors of the aerospace industry, serving a wide range of aircraft types and engines as well as airline operators and maintenance, repair, and overhaul (MRO) facilities.

Safran Group has a presence in 27 countries, with 23.7% of its employees in the Americas. Safran Group has been operating in the United States for almost 50 years and provides filters to some of the most successful companies, such as Boeing and Airbus.

What SoFrance Replacement Filters Does Flutiek Have?

Fluitek carries replacements of three of the most widely used filters that SoFrance makes. The filter types include:

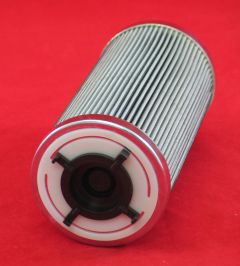

Hydraulic Filters

Hydraulic filters are essential for aeronautical applications. On aircraft, the hydraulic systems that control flight surfaces, landing gear, and other functions require maximum uptime and reliability. Filters trap debris from dirt, dust, and other contaminants that could cause malfunctions. They are vital to protecting precision hydraulic components and ensuring the safe operation of lifesaving systems.

Hydraulic filters also serve in defense and space systems. On military vehicles, they support the operation of turrets, weapons, and other machinery in harsh environments. They are capable of filtering to an extremely fine level to protect sensitive components.

In space applications, hydraulic filters help enable functions like robotic arm movement and landing gear on space vehicles and stations. They remove microscopic particles that could compromise precision requirements in zero-gravity environments. For defense and space, filters designed to withstand temperature extremes and vibration are essential to hydraulic system integrity in demanding conditions.

Spin-on Elements

In aeronautics and defense applications, spin-on elements are well-suited due to their compact cylindrical design and rapid serviceability. Their robust construction can withstand the vibration and impacts encountered in aircraft and vehicles. The self-contained and easily replaceable cartridge minimizes downtime for maintenance or repairs. This makes spin-on elements ideal where rapid replacement of consumable parts is required.

Spin-on elements are also commonly used in space programs where weight, size, and service intervals are important considerations. Their low-profile design efficiently uses limited interior space onboard spacecraft. Multiple housing configurations provide flexible installation options onto manifolds.

Consistently performing filter media is achieved without compromising flow. The proven sealing ability of spin-on elements allows them to withstand launch and environmental stresses. Their burr-free construction prevents contamination issues in microgravity environments.

Suction Screen Elements

In aeronautics applications, suction screen elements, a type of metal element, are well-suited for filtering larger volumes of fluids. The durable metal screens capture debris without clogging, ensuring hydraulic components remain protected even during high-particle events.

Suction screen elements are also used in defense systems that require resilient filtration under extreme conditions. On armored vehicles operating in harsh off-road environments, suction screens reliably filter fluids while withstanding dust, moisture, and temperature fluctuations. The corrosion-resistant construction maintains filtering performance during prolonged field use.

For space programs, suction screen elements are implemented to filter fluids on stations and propulsion systems. Their compact form factor conveniently integrates into tight machinery compartments. Multiple screen rating options allow balancing flow needs versus filtration precision at different vehicle stages. Laser-cut screens further improve durability and prevent particulates from contaminating zero-gravity systems.

Contact Fluitek to determine what SoFrance filter replacement is right for you.

Founded in 1975, Fluitek is a leading supplier of filter replacement elements. With over 35 years of experience, we offer over 250,000 compatible replacements for original equipment filters used in industrial, commercial, and automotive applications.

Our filter representatives have created a cross-reference system that exceeds any other in the market. When you buy from us, you get filters that exceed the OEM's specifications. Our fast shipping is accompanied by affordable prices on the parts you need. So when you purchase filter replacements from us, you're saving an average of 30-50% more. Find the filter you need with Fluitek today!